EHS stands for Environmental Health and Safety—a comprehensive approach that protects your employees, workplace, and surrounding community from potential hazards.

Many organizations struggle with scattered safety data, complex regulatory requirements, and time-consuming compliance tasks. When employees can’t quickly access critical chemical safety information—like through Safety Data Sheets (SDS)—even routine tasks become risky. The good news? A well-designed EHS program doesn’t have to be overwhelming. With the right approach and tools, you can streamline safety management while building a workplace culture that prioritizes employee well-being.

In this guide, we’ll walk you through everything you need to know about EHS management—from core components to implementation strategies that work in the real world.

What is EHS? Understanding the Core Components

EHS encompasses three interconnected areas: Environmental protection, occupational Health, and workplace Safety. This comprehensive framework helps organizations identify hazards, implement protective measures, and maintain regulatory compliance—especially valuable for healthcare, educational, and manufacturing facilities where employees interact with hazardous materials.

Environmental Protection: Safeguarding Your Community

Environmental protection focuses on minimizing your organization’s environmental impact while meeting environmental regulations. Key areas include:

- Hazardous waste management – Proper disposal of chemicals, pharmaceuticals, and contaminated materials

- Pollution prevention – Controlling air and water emissions to protect surrounding communities

- Sustainable practices – Energy conservation and resource management that benefit operations and the environment

For example, a hospital’s environmental protection efforts might involve safely disposing of pharmaceutical waste, managing chemical storage areas, and monitoring energy consumption. These practices protect both employees’ health and environmental stewardship goals.

Occupational Health: Protecting Employee Well-being

The health component addresses long-term employee well-being through medical surveillance, exposure monitoring, and preventive care programs. This is where EHS managers focus on protecting workers from occupational health risks like chemical exposure, respiratory hazards, and ergonomic injuries.

Essential occupational health programs include:

- Medical surveillance – Regular health screenings and exposure assessments for at-risk employees

- Air quality monitoring – Tracking workplace contaminants and ensuring safe breathing environments

- Ergonomic programs – Preventing musculoskeletal injuries through proper workplace design and training

Healthcare organizations, for instance, might track exposure to cleaning chemicals or implement ergonomic assessments for staff who lift patients regularly.

Workplace Safety: Preventing Accidents and Injuries

Safety management concentrates on immediate hazard control and accident prevention. This encompasses everything from maintaining current Safety Data Sheets (SDS) for chemical hazards to implementing personal protective equipment requirements and emergency response planning.

Core workplace safety elements include:

- Personal protective equipment – Ensuring proper selection, use, and maintenance of safety gear

- Emergency preparedness – Developing response plans for chemical spills, fires, and medical emergencies

- Safety training programs – Regular education that helps employees recognize and respond to potential hazards

Effective workplace safety means having clear safety protocols for daily operations, regular safety audits, and comprehensive training that helps employees recognize and respond to safety issues. From university chemistry labs to construction sites, these protocols form the foundation of injury prevention.

Navigating EHS Regulations and Compliance Requirements

Regulatory compliance forms the backbone of any successful EHS program. In the United States, multiple government agencies oversee different aspects of environmental health and safety, each with specific requirements that affect how organizations manage hazardous materials and protect employees.

Federal Oversight: OSHA and EPA Requirements

OSHA governs workplace hazard communication including SDS, while EPA regulates environmental releases and waste; state rules may be stricter.

State and local governments often add stricter requirements beyond federal standards, creating layered compliance obligations that EHS departments must navigate.

Essential Compliance Activities

- Maintain current SDS and chemical inventories

- Train employees on safety protocols and hazardous materials handling

- Document safety issues and conduct regular audits

Why Compliance Matters

Non-compliance carries serious consequences: OSHA fines reach $165,514 for willful violations, EPA penalties can exceed $100,000 per day, and violations damage your reputation while increasing insurance costs.

Building an Effective EHS Management System

Creating a successful EHS program starts with understanding your specific workplace hazards and regulatory requirements. Rather than implementing a one-size-fits-all approach, effective EHS management systems adapt to your organization’s unique needs while maintaining compliance with safety regulations.

Start with Comprehensive Risk Assessment

Begin by conducting a thorough evaluation of your workplace hazards. This assessment should identify potential hazards from chemical exposure, environmental risks, and occupational safety concerns specific to your industry. For healthcare organizations, this might include pharmaceutical waste and infectious materials. Educational institutions often focus on laboratory chemicals and maintenance operations.

Document everything you find. This baseline assessment becomes the foundation for your entire EHS program and helps prioritize safety improvements that will have the biggest impact on employee well-being.

Develop Clear, Practical Policies

Write EHS policies in plain language that translate regulatory requirements into practical, actionable steps employees can easily follow in their daily work.

Effective policies cover:

- Hazardous materials handling and storage procedures

- Personal protective equipment requirements and usage

- Emergency response protocols for different scenarios

- Incident reporting and investigation processes

- Training requirements and schedules

Training, Technology, and Continuous Improvement

A strong EHS program depends on consistent training, smart tools, and regular program evaluation:

- Training: Provide onboarding and refresher courses so employees understand hazards, safe work practices, and emergency procedures.

- Technology: Use centralized systems for SDS management, chemical inventories, and incident reporting to improve access and tracking.

- Continuous Improvement: Conduct regular audits, investigate incidents, and track near-miss reports to identify trends and prevent future issues.

The Business Case: Benefits and ROI of Strong EHS Programs

Organizations that prioritize EHS management see measurable returns across multiple business areas. Beyond the obvious benefits of protecting employees’ health and meeting regulatory requirements, effective safety programs deliver tangible financial advantages that strengthen your bottom line.

Reduced Costs and Improved Efficiency

Companies with comprehensive EHS programs typically experience fewer workplace accidents compared to industry averages. This translates directly to lower workers’ compensation claims, reduced insurance premiums, and decreased downtime from safety incidents.

Operational Excellence and Employee Retention

Proper safety protocols improve overall operational efficiency. When employees feel confident about workplace safety, productivity increases. A strong safety climate is associated with higher job satisfaction and lower turnover intention.

Healthcare organizations particularly benefit from this stability. High turnover in clinical settings can compromise patient care and increase training costs. A strong EHS program helps retain experienced staff who value safe working conditions.

Competitive Advantages

Companies with excellent safety records often qualify for better insurance rates, preferred vendor status with major clients, and enhanced reputation in their markets. This is especially valuable for organizations bidding on government contracts or working with safety-conscious clients.

Environmental stewardship also attracts top talent and supports corporate sustainability goals. Many professionals actively seek employers who demonstrate genuine commitment to employee well-being and environmental protection.

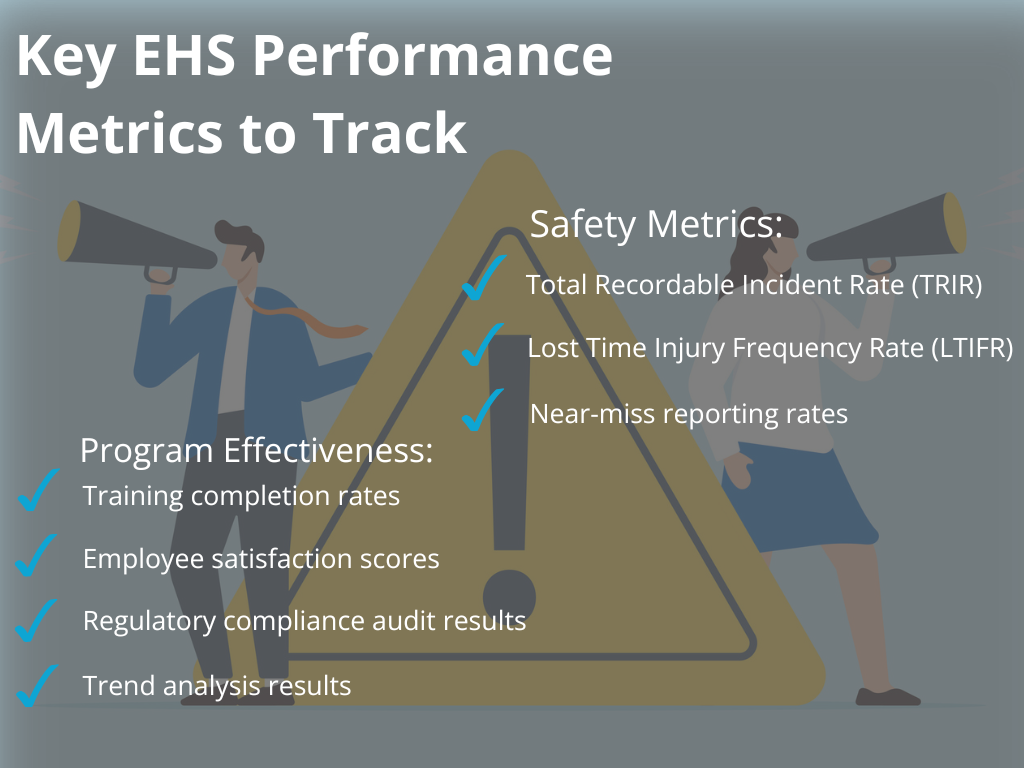

Measuring EHS Performance

Track your program’s success through key metrics:

- Total recordable incident rate (TRIR)

- Lost time injury frequency rate (LTIFR)

- Near-miss reporting rates and trend analysis

- Training completion rates and employee satisfaction scores

- Regulatory compliance audit results

Your Next Steps: Building a Safer, More Compliant Workplace

Effective EHS management doesn’t have to be complicated or overwhelming. The key is starting with a clear understanding of your workplace hazards, implementing practical solutions that fit your operations, and using tools that make compliance manageable rather than burdensome.

Success comes from combining proper training, clear procedures, and technology that actually helps rather than hinders your daily operations. Whether you’re managing a single facility or multiple locations, the principles remain the same: identify hazards, implement controls, train your team, and monitor performance.

Ready to Streamline Your EHS Program?

Managing safety compliance and chemical inventories shouldn’t be overwhelming. The right EHS management software makes all the difference by organizing complex information and ensuring quick access when you need it.

M3V’s EH&S Task Manager was built by experienced chemists and engineers who understand real-world EHS challenges. Our all-in-one solution combines SDS management, chemical inventory tracking, and task management in one intuitive system.

What sets M3V apart:

- Expert-Built Solutions: Developed by seasoned professionals who’ve faced these challenges firsthand

- Intuitive Design: Non-technical users can manage complex safety data efficiently

- Flexible & Scalable: Adapts from single facilities to multi-campus operations

- All-in-One Platform: Eliminates multiple disconnected systems

- Exceptional Support: Responsive, expert-level assistance for long-term success

Ready to see M3V in action? Schedule a demonstration today and discover how our specialized software helps organizations maintain compliance, reduce risk, and create safer workplaces.