We recently surveyed EHS managers, safety coordinators, and operations professionals to better understand how they manage their safety data sheets (SDS) and the results were eye-opening. Our survey included a diverse group of end users including small – medium sized manufacturers, municipalities, state and federal governmental agencies, health care networks, regional hospitals, distributors and more. The challenges around SDS management are surprisingly universal, yet the path to solving them is clearer than many organizations realize.

Survey Methodology

Our comprehensive survey reached safety professionals across eight diverse organizations, representing a cross-section of industries that rely heavily on chemical safety compliance. Respondents included Safety Coordinators, Environmental Engineers, Risk Managers, Compliance Managers, and Utility Managers from:

- Manufacturing companies (automotive, stainless steel, animal feed)

- Municipal organizations (city governments, wastewater treatment)

- Utilities (public utility districts)

- Distribution companies (beer wholesaling)

These professionals are responsible for managing chemical safety data and regulatory compliance across facilities ranging from single-location operations to multi-site organizations with complex distribution networks.

Key Findings: The Current State of SDS Management

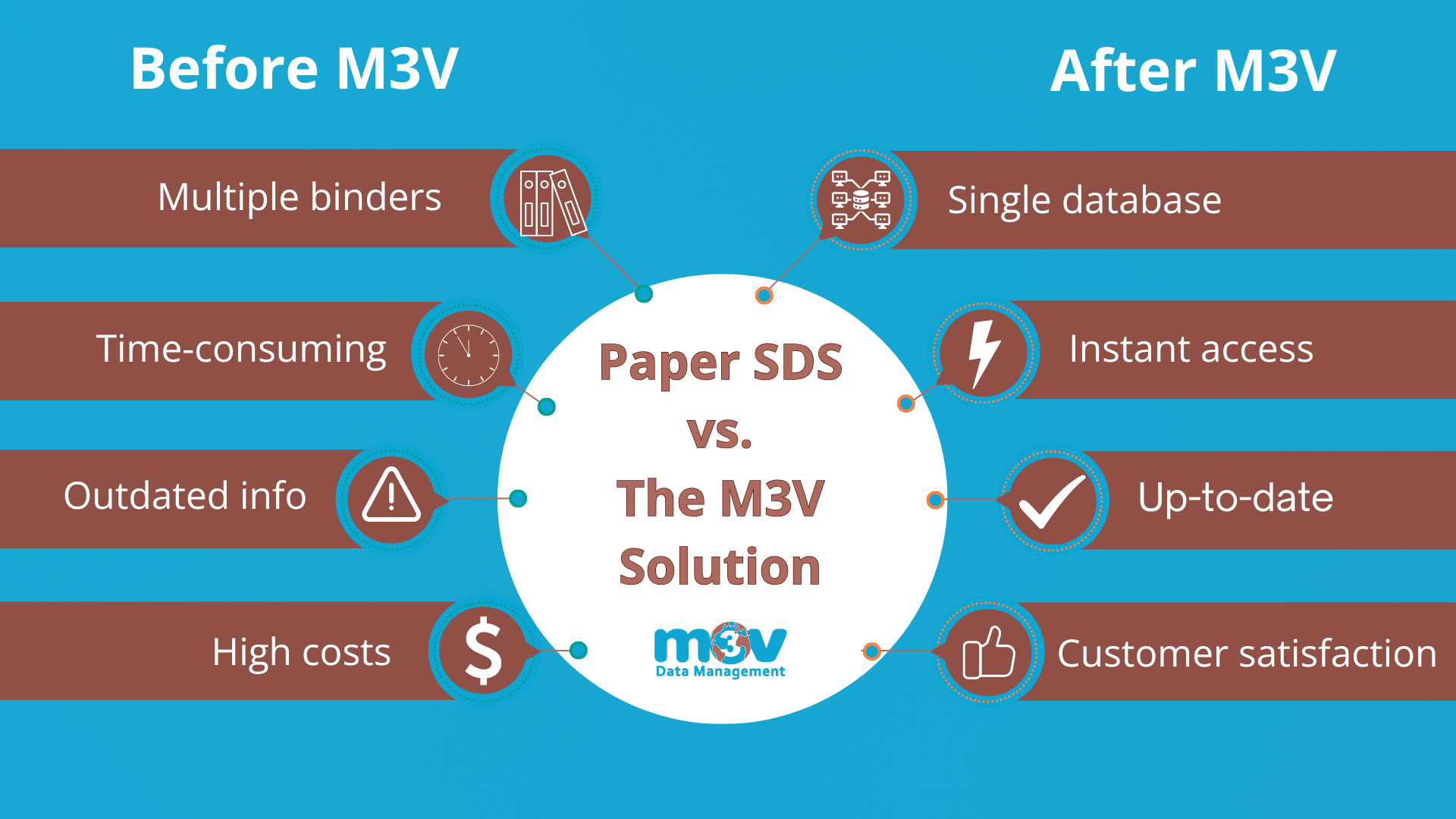

1. Paper-Based Systems Still Dominate And They’re Failing Organizations

The Reality: Despite all the digital accessibility these days, 75% of survey respondents were still managing SDSs through paper binders before switching to M3V.

The challenges with paper systems were consistent across all organization types:

- Multi-location nightmares: Fred Coutinho, Compliance Manager at Kalmbach Feeds, described the core problem: “Updating binders at multiple locations when we received revised or new SDSs.”

- Accessibility barriers: Candice Baker, Safety/Environmental Manager at Felker Brothers, explained that “SDS binders were only available in physical locations making it difficult for employees to access critical safety information quickly.”

- Maintenance burden: One Environmental Engineer described paper SDS systems as creating “outdated SDS’s, difficult to manage, lots of paper waste, not convenient” — capturing the frustration many organizations feel with manual processes.

For organizations with multiple facilities, the paper approach creates an exponential maintenance problem—every update requires physical visits to multiple locations, leading to inevitable gaps in compliance and employee safety.

2. Customer Support Outshines Features in Platform Selection

The Surprise: While most organizations start their search focusing on features and functionality, customer service emerged as the decisive factor in platform selection.

David Eichermuller, Fleet and Safety Manager at North Florida Sales, was emphatic: “CUSTOMER SERVICE WAS #1!” when evaluating platforms, and ultimately “CUSTOMER SERVICE!” was why they chose M3V.

This pattern repeated across responses:

- Ben Bouch cited “Cost, Ease of Use, Support” as key factors

- Brian Davison prioritized “Ease of use and customer support”

- An environmental engineer listed “Cost, ease of use, customer support, compliance”

Why this matters: Safety professionals often work in lean teams with limited technical support. When compliance issues arise, they need responsive help—not a ticket system or lengthy wait times.

3. Contract Flexibility Is a Hidden Deal-Breaker

One of the most revealing insights came from Peter Scarlett, Safety Coordinator at Aggrowth International Inc., who specifically mentioned that he “didn’t like being locked into a 3 year contract” with his previous provider (another system).

This highlights a crucial but often overlooked factor: safety teams need the flexibility to adapt their solutions as organizational needs evolve. Long-term contracts can trap organizations with tools that no longer serve their changing requirements.

4. Real-World Accessibility Drives Measurable Results

The most successful M3V implementations focus on making SDS information accessible exactly where employees need it:

- Shop floor tablets: Peter Scarlett’s team “made it more accessible by making it available on Tablets used by employees on the shop floor”

- QR code integration: David Eichermuller’s organization “set up QR codes throughout our facilities which take them to the website so they can view our library of SDS sheets (without the need to enter log in information)”

- Intranet integration: Fred Coutinho’s company has “a link on the company intranet website that anyone can click on to access our database on M3V”

This practical accessibility translates to measurable improvements in safety compliance and operational efficiency.

5. Time Savings and Accuracy Improvements Are Immediate and Quantifiable

Organizations reported consistent, measurable improvements after implementing M3V:

Time Savings:

- Ben Bouch: “SDS management time is cut down considerably”

- Anonymous: “Much faster to update ONE place (the database) rather than updating multiple physical locations”

- Candice Baker: “Time savings, improved compliance, inventory accuracy, and audit efficiency”

Accuracy and Compliance:

- Fred Coutinho: “It has saved us time and ensured accuracy since we have a central database”

- Brian Davison: “More accurate records of the chemicals on hand”

- Environmental engineer surveyor: “SDS’s are current” and “improved awareness, better management of SDS’s, compliance”

What It Means for Safety Teams

These findings reveal that successful SDS management isn’t about finding the most feature-rich platform—it’s about implementing a solution that works in the real world. Safety teams are looking for tools that:

Eliminate the Multi-Location Update Nightmare: Centralized digital systems that automatically sync across all locations, ending the cycle of manual binder updates and ensuring consistency.

Provide Instant Access Where Work Happens: Whether that’s on shop floor tablets or other mobile devices, through QR codes, or via intranet links, employees need safety information at the point of need, not locked away in a supervisor’s office.

Come with Responsive Human Support: When compliance questions arise, safety professionals need expert guidance quickly. The quality of customer service often determines whether a platform helps or hinders compliance efforts.

Offer Flexibility for Changing Needs: Organizations evolve, and their SDS management needs change. Platforms with flexible pricing levels and adaptable features prevent teams from being trapped in solutions that no longer serve them.

The survey also highlights that the transition from paper to digital, while intimidating, can be remarkably smooth with the right support. As Candice Baker noted: “Transitioning from a manual system of binders and spreadsheets to a digital platform can be daunting, but M3V made it manageable.”

How M3V Addresses These Real-World Challenges

M3V was purpose-built to solve exactly the challenges highlighted in our survey:

Centralized Digital Management: Instead of maintaining multiple physical binders, organizations manage everything from one central database that automatically updates across all access points. As one surveyor experienced: it’s “much faster to update ONE place (the database) rather than updating multiple physical locations.”

Flexible Access Options: M3V works wherever your employees work—on shop floor computers, tablets and other mobile devices, through QR codes, or integrated into existing intranet systems. The platform adapts to your workflow, not the other way around.

Industry-Leading Customer Support: Our survey confirms what we’ve always prioritized: responsive, expert customer service. As David Eichermuller put it, M3V offers “some of the best customer service in the industry.” When compliance questions arise, you get answers from people who understand your challenges.

No Long-Term Contract Lock-In: Unlike competitors with restrictive multi-year commitments, M3V offers flexible pricing that grows with your organization and adapts to changing needs.

Proven Track Record: With customers like ours — including one that has “partnered with M3V for over 13 years and never had any issues” — our platform has demonstrated long-term reliability and continuous improvement.

The Bottom Line: 100% Customer Satisfaction

Perhaps the most telling statistic from our survey: every single respondent would recommend M3V to other companies.

From Peter Scarlett’s strong endorsement (“I would strongly recommend M3V to any company”) to Candice Baker’s confident recommendation for companies “looking to modernize their SDS management,” the message is clear: M3V delivers on its promises.

As an Environmental Engineer summarized: “M3V has made this aspect of my job much easier.”

Ready to Transform Your SDS Management?

If the challenges described in our survey sound familiar, you’re not alone. Safety teams across industries are discovering that the right SDS management platform transforms compliance from a time-consuming burden into a streamlined, accessible process that actually improves workplace safety.

Want to see exactly how M3V can simplify your SDS management process? Request a quote or schedule a demo and discover why 100% of our customers recommend M3V for flexible, user-friendly SDS management that works in the real world.