Big picture takeaway: The transition from Material Safety Data Sheets (MSDS) to Safety Data Sheets (SDS) represents a significant advancement in global hazard communication standards, with SDS offering a more standardized and comprehensive 16-section format. This evolution, implemented through the United States’ adoption of the Globally Harmonized System (GHS), has made chemical hazards information more accessible, consistent, and easier to understand across international borders.

The way we communicate hazardous chemicals has undergone substantial changes over the years. Before 2003, the MSDS format varied widely in structure and presentation, making it challenging for chemical manufacturers to maintain consistency and clarity in safety documentation. The introduction of Safety Data Sheets brought a new level of standardization to hazardous product information.

OSHA’s Hazard Communication Standard

OSHA’s Hazard Communication Standard (HCS) stands as the foundation of occupational safety in the United States. The program requires employers to inform employees about chemical hazards through a systematic approach to hazard classification and safety management. The HCS consists of five main elements that work together to protect workers including written hazard communication plan documentation, chemical inventory lists, secondary container labeling, unimpeded safety data sheet access, and employee training.

Historical Development

The standard has evolved significantly since its introduction in 1983. A major update occurred in 2012 when OSHA aligned the HCS with the Globally Harmonized System (GHS). This change moved the U.S. from the Material Safety Data Sheet (MSDS) format to the standardized SDS format with 16 specific sections.

The Evolution from MSDS to SDS

The evolution from material safety data sheet (MSDS) to safety data sheet (SDS) represents a significant shift in how businesses communicate chemical hazard information. Before 2003, MSDS formats varied widely between organizations, creating potential hazards and inconsistency in hazard communication.

Change in Safety Documentation

Material safety data sheets emerged as the standard way to document hazardous chemical information, but their non-standardized nature led to varying MSDS formats across chemical manufacturers and countries. Each MSDS contained basic sections covering chemical product information, hazardous materials, physical data, and protective measures, but the presentation and depth of information could differ substantially between providers.

The Push for Change

Three main factors drove the transition to SDS:

- Global trade expansion created a need for standardized chemical classification documentation

- Varying MSDS formats caused confusion and potential safety risks

- Different documentation requirements between countries created trade barriers

Implementation Timeline

The United Nations established the Globally Harmonized System of Classification and Labelling of Chemicals (GHS) in 2003, marking the beginning of worldwide SDS adoption. OSHA formally adopted the SDS system in 2012, giving United States companies until June 2015 to complete their transition. The implementation occurred in phases:

- Phase 1: Employee training on new labels and formats

- Phase 2: Compliance with new SDS format requirements

- Phase 3: Updates to workplace labeling and hazard communication programs

Workplace Impact

The switch to SDS brought a consistent 16-section format that improved hazard communication across industries. Workers now have clearer access to safety information through standardized sections covering everything from first aid measures to handling and storage. This standardization helps reduce workplace incidents by providing uniform safety guidance.

The new format also added environmental hazards as a distinct category alongside physical and health hazards, reflecting growing awareness of environmental protection in chemical handling. This improvement in documentation has helped companies better protect both workers and the environment while simplifying regulatory compliance requirements.

MSDS vs. SDS: A Detailed Comparison

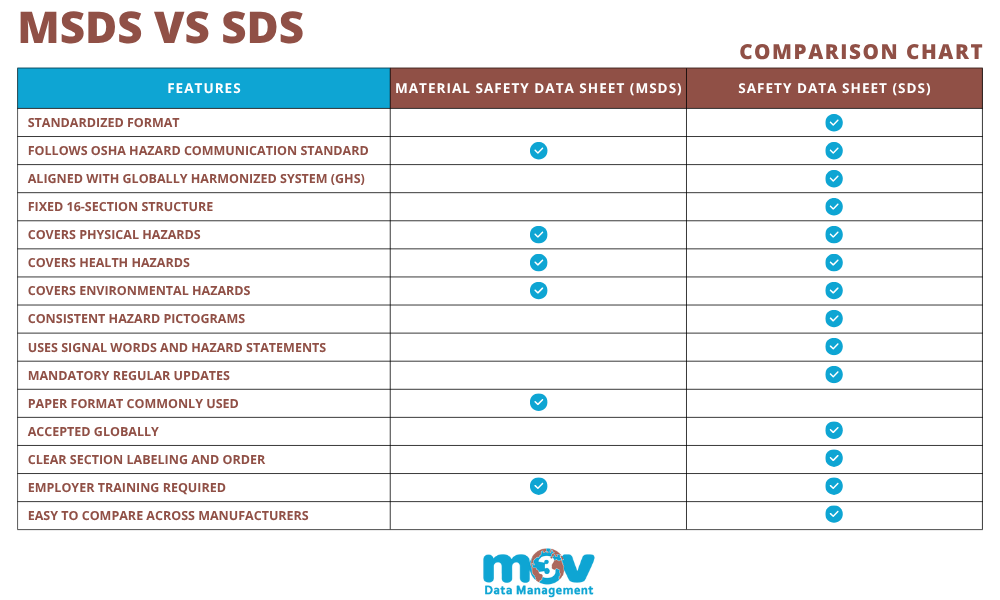

Format Differences

Material Safety Data Sheets (MSDS) followed a variable MSDS format with basic sections that could differ between chemical manufacturers. These typically included chemical product information, hazardous ingredients, physical data, and first-aid instructions.

In contrast, Safety Data Sheets (SDS) follow a standardized 16-section format under the Globally Harmonized System (GHS). This structured approach includes sections from chemical identification to other information, with four non-mandatory sections covering environmental hazards, disposal considerations, transport, and regulatory requirements.

Symbols and Labeling

MSDS documents used organization-specific hazard statements, typically displayed as color-coded pictograms in diamond or square shapes. These symbols varied depending on the issuing organization’s standards.

The transition to SDS brought uniform GHS standards and signal words, making hazard communication consistent across different countries and manufacturers. This standardization helps workers and emergency responders identify potential hazards quickly, regardless of their location.

Hazard Categories

The hazard classification system has evolved significantly. MSDS primarily focused on two main categories:

- Physical hazards (immediate dangers like hazardous materials and flammable liquids)

- Health hazards (both acute and chronic risks like carcinogens and toxins)

SDS maintains these categories while adding a third important component:

- Environmental hazards (impact on ecosystems and natural resources)

Regulatory Requirements

Documentation requirements have become more structured under SDS requirements. While MSDS had varying requirements by jurisdiction, SDS follows strict GHS guidelines. The update frequency for MSDS and SDS varies by manufacturer.

The accessibility standards have also improved. While MSDS documents were maintained differently across organizations, SDS must be readily available to workers, with many companies now offering digital solutions. The standardization through GHS has made chemical safety information more accessible and understandable across supply chains.

The Future of Chemical Safety: Why Digital SDS Management Matters

Digital SDS management software offers automated document control and instant electronic access to safety data sheets across an organization. This technology replaces outdated hard copy systems, helping companies maintain regulatory compliance, and removing a barrier to access to employees. Digital SDS management allows access without searching for binders by chemical type or manufacturer name.

In today’s workplace, managing safety data sheets has become more complex than ever. As businesses handle increasing numbers of hazardous products, the old method of storing paper documents in binders creates risks of outdated information and delayed access during emergency response. The movement toward digital solutions addresses these challenges while providing advantages that paper systems cannot match.

Benefits of Digital SDS Management

Modern SDS management platforms provide several important capabilities:

- 24/7 access to up-to-date safety information from any device

- Automatic updates when manufacturers revise documents

- Built-in compliance tracking and reporting tools

- Reduced manual data entry and filing tasks

- Immediate document retrieval during incidents

- Multi-location access and standardization

The Business Case for Digital Solutions

For organizations working with hazardous materials, digital SDS management isn’t optional – it’s a practical necessity. As global regulations continue evolving and chemical inventories grow more complex, paper-based systems become increasingly difficult to maintain. Digital platforms help companies stay compliant while improving worker safety through better information access.

Looking to upgrade your SDS management approach? M3V Data Management offers web-based solutions that simplify regulatory compliance and chemical safety documentation. Our purpose-built software helps safety professionals maintain accurate records and access critical safety information when it matters most. Contact us to learn how we can help modernize your SDS management system.