The Short Answer: Physical SDS binders are outdated and create unnecessary risks for workplace safety and compliance. Digital SDS management systems offer faster electronic access to safety information and automatic updates that keep your work area protected.

Safety Data Sheets (SDS) provide detailed information about chemical hazards and safety procedures—documentation that workers and emergency responders need to handle hazardous materials properly. While traditional SDS binders have been a workplace standard for decades, they present significant challenges in today’s fast-paced industrial environment. These physical documents often become outdated, damaged, or misplaced when workers need them most.

Many employers struggle with maintaining paper SDS collections, facing issues like missing pages, outdated chemical safety information, and time-consuming manual updates. The reality is that paper-based systems can’t keep pace with modern workplace demands, where quick access to accurate safety data can make the difference in emergency situations.

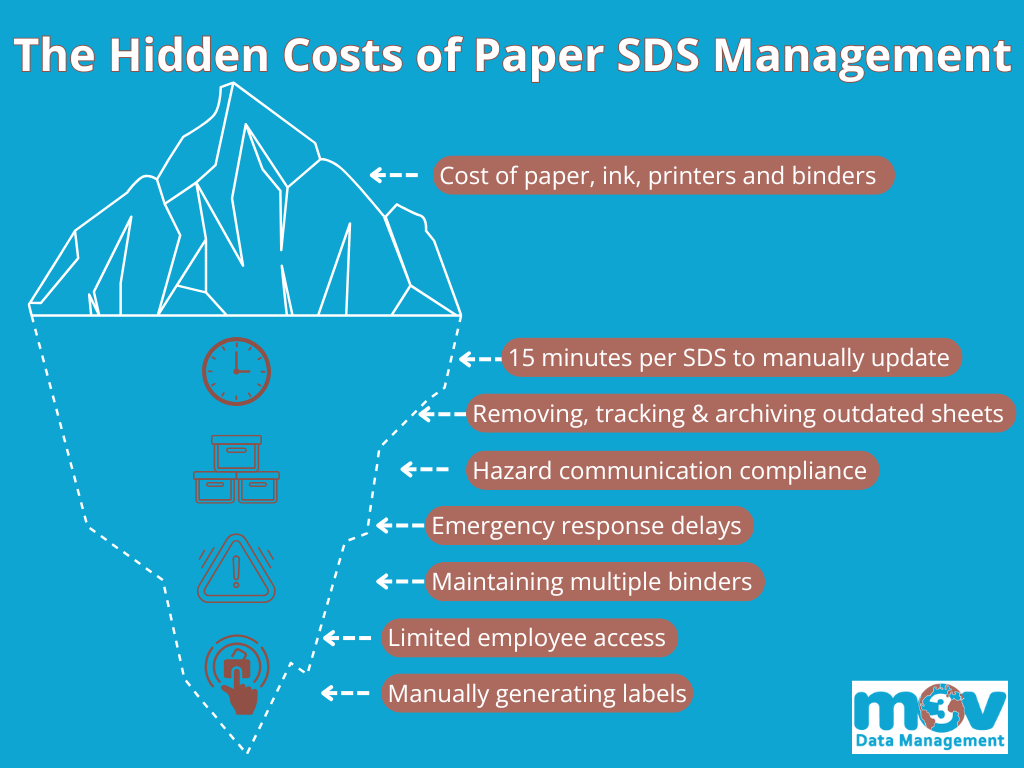

The Hidden Costs of Paper SDS Management

Paper-based Safety Data Sheet (SDS) management creates significant hidden costs through time-consuming manual processes and storage challenges. Companies waste countless hours on administrative tasks while also dealing with storage space requirements and deteriorating SDS sheets.

Time-Intensive Manual Processing

- Staff spends 15-20 minutes updating each new SDS into the correct SDS binder section

- Locating and removing outdated material safety data sheet versions requires hours of work monthly

- Tracking revision dates and removing expired hazardous chemical documents demands constant attention

Physical Storage Burdens

- Multiple SDS binder sets needed at each work area for OSHA requirements

- Bulky MSDS binders consume valuable shelf space

- Climate-controlled storage required to prevent safety data sheet deterioration

- Paper documents become faded, torn and illegible over time

Limited Accessibility Issues

- Only one person can view specific chemical safety information at any time

- Could be indexed by product, manufacturer type, or department

- Workers spend extra time walking to binder locations and searching through pages

- Multi-facility employers face delays sharing updated SDSs between job sites

- Significant Hazcom training to locate the SDS

- Emergency situations hampered by slow access to hazard information

Resource Impact

- Staff time lost to manual filing and updates

- Storage space requirements for SDS binders

- Higher risk of compliance gaps from misplaced or outdated documents

- Productivity reduced by access bottlenecks

- Additional costs for paper, binders and document replacement

Safety and Compliance Risks

Paper-based SDS management and traditional SDS binder systems introduce significant risks that can impact workplace safety and regulatory compliance. Maintaining physical safety data sheet binders leads to three main areas of concern that directly affect an organization’s ability to protect workers and meet OSHA requirements.

1. Outdated Information Risks

Outdated chemical safety information poses a major risk when relying on paper SDS binder management. Manufacturers regularly update their safety data sheets to reflect new hazardous material information, handling procedures, and regulatory changes. With physical binders, these updates can slip through the cracks. Workers might unknowingly follow outdated handling procedures or miss new hazard classifications, putting themselves at risk. A paper system provides no automatic notification when manufacturers revise their documentation.

2. Emergency Response Delays

Emergency response scenarios highlight another weakness of paper SDS management systems. When incidents involving hazardous chemicals occur, quick access to accurate safety information becomes a matter of life and death. Workers must locate the correct MSDS binder, find the specific sheet, and hope it hasn’t been removed or misplaced. These delays can seriously impact first aid response times. In facilities with multiple work areas or buildings, the problem multiplies as staff waste precious minutes searching for the right documentation.

3. Audit and Compliance Challenges

Audit preparation becomes unnecessarily complicated with paper SDS systems. Organizations must prove they maintain current safety data sheets and can demonstrate consistent compliance over time. Paper systems make version control nearly impossible – there’s no reliable way to track when documents were updated or verify that outdated sheets were removed. Documentation gaps appear when sheets go missing from binders. Without a clear audit trail, organizations struggle to prove they’ve maintained proper hazard communication program practices when inspectors arrive.

OSHA Inspection Reality

While OSHA probably won’t visit just to check your SDS management and training, if they’re already on-site for any reason, inspectors often pick 3 chemicals from different areas and ask 3 employees to find the corresponding SDS. Are you prepared for this test? The stakes are high – hazard communication violations consistently rank as the #2 most frequently cited OSHA violation year after year, with only fall protection violations occurring more frequently. This pattern has persisted for decades, demonstrating that many organizations continue to struggle with maintaining compliant SDS management systems.

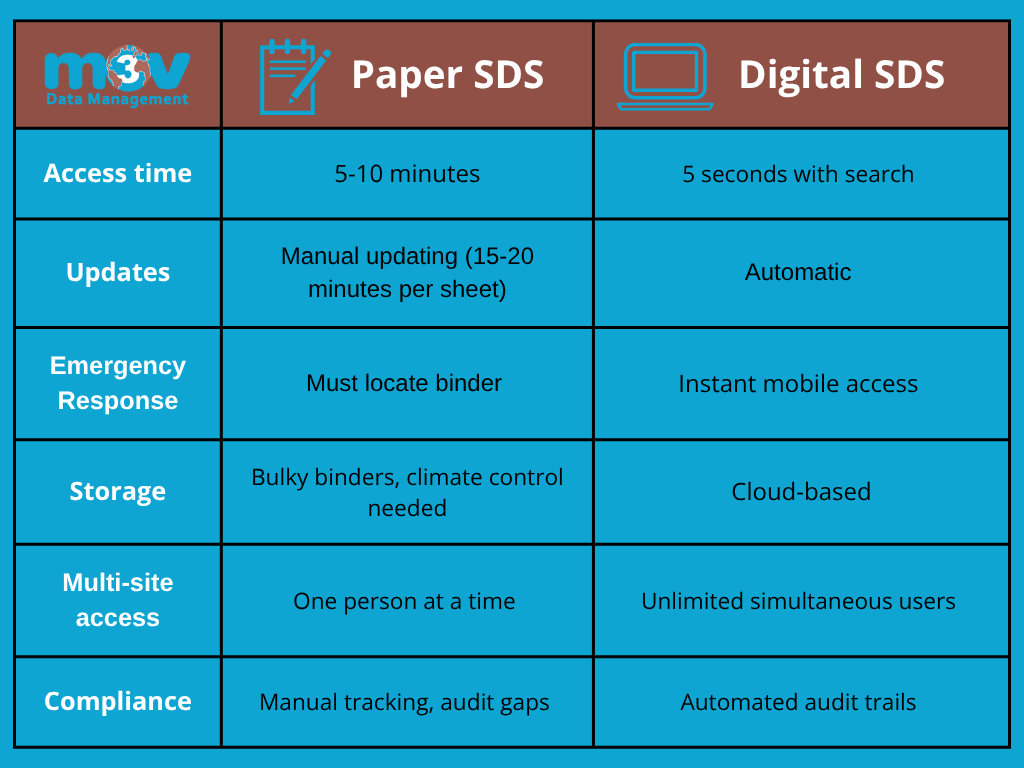

Digital SDS Management Advantages

Digital Safety Data Sheet (SDS) management provides comprehensive solutions that address all the limitations of paper-based systems. These platforms offer mobile accessibility, automated maintenance, and enhanced emergency response capabilities that transform workplace safety management.

Mobile Access and Search Capabilities

Digital SDS platforms make chemical information available through mobile apps and tablets, offering:

- Access from anywhere in the job site

- Quick search by product name, manufacturer, or hazardous chemical ingredients

- Retrieval of safety procedures and handling guidelines

Multi-Site Benefits

Digital systems improve operations across multiple locations by providing:

- Synchronized safety data sheet access for all facilities

- Shared updates across linked sites

- Prevention of outdated or conflicting SDS information

Version Control and Documentation

The digital platform maintains comprehensive records through:

- Automated incorporation of manufacturer updates

- Searchable archives of previous SDS (MSDS) sheets

- Complete documentation for OSHA requirements

- Clear tracking of discontinued SDS’s or products to comply with the OSHA 30 year retention rule

Emergency Response Advantages

Digital systems support faster emergency response with:

- Access to hazardous material exposure protocols

- Ready spill procedures

- Current protective measures requirements

- Real-time chemical hazard information

Practical Safety Applications

Workers can perform workplace safety tasks more effectively by:

- Checking chemical compatibility before mixing products

- Verifying proper handling procedures for new chemicals

- Accessing current PPE requirements

- Reviewing safety protocols on-site

Streamlined Label Generation

Some SDS management systems leverage the chemical data already stored in their databases to automatically generate compliant labels, eliminating manual data entry and reducing errors. These digital systems can print QR codes directly on labels that, when scanned, instantly open the corresponding SDS without requiring database searches or navigation through file systems.

This QR code functionality significantly reduces barriers to OSHA’s required “unimpeded employee access” to Safety Data Sheets. Workers can access critical safety information immediately from any location in their work area using just a smartphone or tablet, whether they’re in remote warehouse locations, working away from computer terminals, or responding to emergency situations.

These practical advantages of digital SDS management deliver better workplace safety outcomes compared to traditional SDS binder systems, making it the superior choice for modern facilities. Digital platforms provide measurable ROI through reduced administrative work, faster compliance audits, and decreased incident response times. Automated label generation with QR codes makes accessing the correct SDS quick and easy, reducing errors and supporting OSHA’s requirement for unimpeded access. Organizations gain confidence with automated updates and complete audit trails, while workers benefit from instant access to safety information that can prevent accidents and save lives. Transitioning to digital SDS management is an investment in worker protection and operational efficiency that improves every aspect of chemical safety management.

Make the Switch

It’s time to retire your paper SDS binder. Digital SDS management isn’t just an upgrade—it’s essential for modern workplace safety. Paper systems put your workers at risk and create compliance headaches that digital solutions solve instantly.

The transition is straightforward: inventory your chemicals, assess your compliance needs, and implement a digital system. Don’t wait for an emergency to expose the weaknesses in your current paper-based approach.

M3V Data Management provides digital SDS solutions built specifically for safety professionals who need reliable, up-to-date chemical documentation. Contact us today to replace your outdated binders with a system that actually protects your workplace.