The proper handling and management of hazardous materials is not just a regulatory requirement—it’s a critical cornerstone of workplace safety and operational continuity. Each year, thousands of hazardous materials incidents occur in workplaces across the United States, ranging from minor hazardous material spills to catastrophic releases that can require emergency response and potentially harm nearby persons.

According to recent industry data, hazardous materials emergencies remain one of the most challenging workplace safety issues, with the federal government receiving 12 reports of hazardous substance releases every day. These events not only pose immediate risks to emergency responders but can also cause costly cleanup operations, regulatory penalties, and potential long-term environmental impact.

Challenges in Managing Hazardous Materials

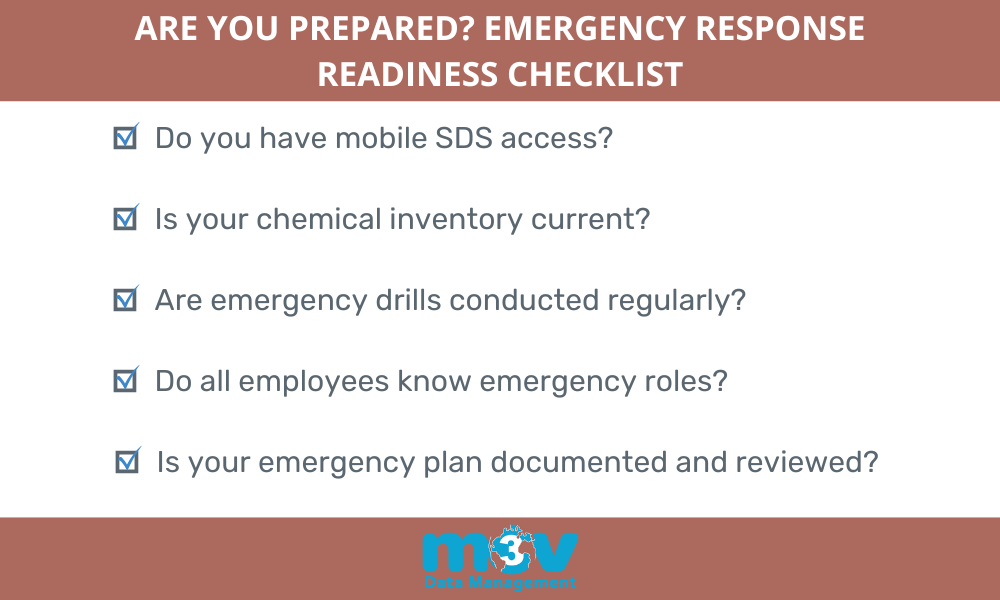

The challenges in managing hazardous materials emergency preparedness are multifaceted. Organizations must contend with evolving regulatory requirements, maintain comprehensive chemical inventories, ensure proper emergency training of response personnel, and coordinate effectively with local agencies during incidents. The complexity is further amplified by the need to maintain up-to-date Safety Data Sheets (SDSs), implement proper labeling systems, and ensure clear emergency response information protocols are in place before an emergency occurs.

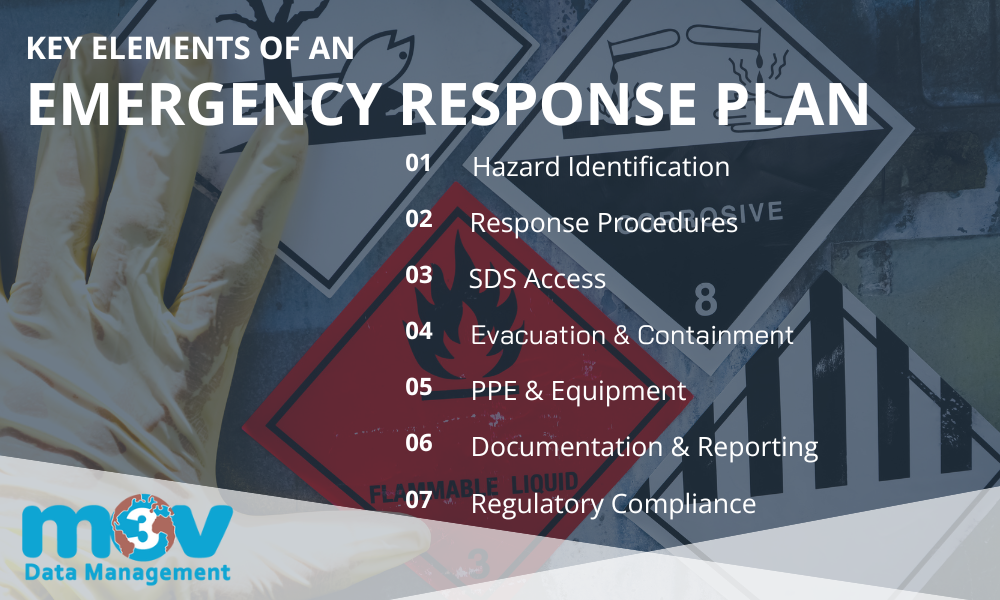

Effective emergency planning encompasses several critical components: thorough hazard assessment, detailed response procedures, regular training and drills, proper documentation systems, and clear communication protocols. Organizations must also ensure they have appropriate spill control equipment, personal protective equipment (PPE), and decontamination facilities readily available. Perhaps most importantly, they need robust systems for managing and accessing critical emergency response information when seconds count.

Understanding Hazardous Materials Emergency Response

Types of Hazardous Material Incidents

Hazardous material incidents and hazardous materials accidents can take many forms, from chemical spills and gas leaks to biological exposures and radioactive material events. Each type of incident requires a specific, coordinated emergency response to protect human health and the environment. Understanding these scenarios and having proper emergency response plans in place is crucial for workplace safety and regulatory compliance.

Initial Response Procedures

When a hazardous materials incident occurs, the first critical steps involve rapid assessment and immediate notification of emergency responders. This includes

- Identifying the nature and scope of hazardous substances

- Securing the affected area

- Activating appropriate emergency response information protocols

- Establishing a controlled perimeter

- Implementing necessary evacuation procedures for nearby persons

- Preventing unauthorized access to the contaminated zone

Emergency Response Team Roles

First responders and emergency response teams play a vital role in managing hazardous material spills through their specialized emergency training and equipment. These teams typically include:

- Hazmat technicians

- Safety officers

- Environmental health professionals

Their responsibilities encompass everything from initial assessment and containment to cleanup operations and post-incident analysis.

Communication and Documentation

Clear emergency response information protocols are essential during hazardous materials emergency preparedness. This includes immediate notification of appropriate personnel, coordination between different local agencies and fire departments, and clear documentation of all actions taken. Safety Data Sheets (SDS) serve as critical reference tools during these events, providing detailed technical assistance about specific chemicals’ properties, hazards, and required response measures.

Safety Data Sheet Management and Compliance

Integrating digital SDS management systems into emergency response plans ensures that emergency responders have immediate access to crucial safety information. These documents contain proper handling procedures, personal protective equipment requirements, and specific emergency measures for each hazardous material. Maintaining current safety data sheet records and ensuring their accessibility during emergencies is not just a best practice – it’s a regulatory requirement under OSHA’s Hazard Communication Standard.

Regulatory Compliance and Updates

Compliance with regulatory standards, including OSHA requirements and EPA guidelines, must be maintained throughout the emergency response process. This includes proper documentation, reporting to appropriate federal agencies, and adherence to specific protocols for different classes of hazardous waste. Organizations must regularly review and update their emergency management plans to ensure they meet current regulatory requirements and industry best practices.

Building an Effective Emergency Response Plan

A well-structured emergency response plan is crucial for maintaining workplace safety and ensuring regulatory compliance in hazardous material management. Modern digital solutions have revolutionized how organizations handle emergency preparedness, particularly through integrated SDS management systems.

The foundation of an effective emergency response plan begins with comprehensive hazardous materials emergency preparedness. At its core, this includes the seamless integration of SDS management software that provides immediate access to critical emergency response information. This digital infrastructure enables real-time documentation of hazardous materials inventory and automated compliance tracking, ensuring that safety information is always current and readily available for emergency responders.

- Risk assessment and hazardous material incident identification become more precise through advanced safety data sheet management systems. You should be able to automatically identify potential toxic substances interactions and flag incompatible materials.

- Emergency response team roles require clear delineation and digital support. First responders need defined access protocols for the digital SDS database, with designated personnel responsible for maintaining electronic safety documentation.

- Evacuation and containment procedures benefit significantly from technology integration. Mobile access to emergency response information enables responders to make informed decisions during emergencies. Quick retrieval of containment protocols through software ensures that response teams can act swiftly and appropriately based on the specific chemicals involved.

- Documentation and reporting requirements are streamlined through electronic incident reporting systems. These platforms provide automated regulatory compliance updates and enable efficient digital archiving of safety records and SDS sheets. This comprehensive approach to digital documentation ensures that organizations maintain accurate records of incidents and responses while meeting all regulatory obligations.

- Emergency training and drill protocols have evolved to incorporate virtual elements. Regular training sessions focus on SDS management system usage and accessibility, while software-based emergency response simulations provide practical experience in a controlled environment.

By leveraging modern SDS management solutions and digital tools, organizations can build and maintain more effective emergency response plans that protect both personnel and facilities while ensuring regulatory compliance.

Implementing Safety Data Sheet Technology Solutions

The Digital Evolution of Workplace Safety

Digital solutions have become instrumental in strengthening emergency response capabilities and hazardous material management. Modern Environmental Health and Safety (EH&S) management demands sophisticated technological tools that can deliver emergency response information instantly while maintaining comprehensive documentation of safety protocols and hazardous materials incidents.

Mobile-First SDS Management

Cloud-based SDS management platforms provide emergency responders with immediate access to vital safety information through secure mobile applications, ensuring that critical hazardous substances data and emergency procedures are available 24/7. This mobile accessibility proves invaluable when first responders need instant access to chemical properties, exposure protocols, or containment procedures.

Integrated Emergency Communications

Advanced emergency response plan systems can simultaneously alert multiple stakeholders through various channels—including mobile alerts, email notifications, and facility-wide announcements—while maintaining detailed documentation of all emergency response information and activities. Real-time hazardous materials incident reporting capabilities allow organizations to document events as they unfold, capturing crucial details that might otherwise be lost in the chaos of an emergency situation.

Smart Facility Management and Control

Facility management integration extends beyond communication to include automated monitoring systems, electronic access controls, and emergency management protocols. Modern data management tools support this infrastructure by maintaining detailed electronic records of emergency training, inspections, and incident reports, ensuring organizations meet compliance requirements while providing valuable insights for continuous improvement of emergency response protocols.

Building a Responsive Safety Culture

These technological solutions not only enhance emergency preparedness but also streamline routine hazardous material safety operations, creating a more robust and responsive safety culture. By leveraging these digital tools, organizations can significantly improve their emergency response capabilities while maintaining the detailed documentation necessary for regulatory compliance and ongoing safety program evaluation.

M3V Software to Improve Emergency Response

Critical to this endeavor is the systematic management of emergency response information. M3V’s advanced SDS management system ensures that Safety Data Sheets are instantly accessible to emergency responders, while their hazardous material tracking capabilities provide real-time visibility of hazardous substances locations and quantities. This immediate access to crucial safety information can significantly improve response times and effectiveness during emergencies.

Organizations seeking to enhance their emergency preparedness can leverage M3V’s integrated solutions to create a comprehensive emergency management system. From maintaining current chemical inventories to tracking regulatory compliance, their software provides the tools needed to protect both personnel and facilities.

The time to prepare for an emergency is before it occurs. Contact M3V Data Management to transform your hazardous materials emergency response capabilities through efficient, accurate, and accessible emergency response information. Your commitment to emergency readiness not only ensures regulatory compliance but, more importantly, protects your most valuable assets – your people and your organization.